Black Hawk Parts Things To Know Before You Buy

Wiki Article

Getting My Black Hawk Parts To Work

Table of ContentsA Biased View of Black Hawk PartsThe smart Trick of Black Hawk Parts That Nobody is Talking AboutBlack Hawk Parts Fundamentals ExplainedBlack Hawk Parts for Beginners

KAMAN K-1200 K-Max synchropter In a side-by-side blades setup, two horizontal, counter-rotating blades are mounted side-by-side on a helicopter (or transverse rotorcraft). black hawk parts. The anti-torque result is offered by the opposing turning of both primary rotors. The side-by-side configuration is one of the possible trip setups of a tilt-rotor airplane, when the rotors remain in the upright position to supply upright lift.It is vital that components are developed and also ended up in a right fashion. As a helicopter spare components dinner in the United States, Jones Metal Products is right here to form and also complete helicopter components in an exact and also timely fashion. Jones Metal Products has more than 95 years in the hydroforming market, a process that we utilize for a variety of components in the aerospace and also defense sectors.

As a helicopter parts distributor, Jones Steel Products regularly welcomes outside organizations in for proper certifications. These outside companies observe and also verify the various processes that we have on deal where we are making consistent advances in composite manufacturing of helicopter components. ISO 9001:2015 without Design This certification connections to our top quality administration system.

When it becomes a relied on and valued helicopter components manufacturer, making developments in composite production of helicopter parts features the territory. The processes whereby we produce helicopter parts are always being enhanced upon by our experienced group. Our team of designers, designers, and metalworkers have actually been innovating our services given that the 1920s.

Not known Facts About Black Hawk Parts

They can even aid you to recreate older helicopter components that stem from stopped runs all while keeping in line with our high criteria of top quality and also consistent production. Hydroforming, Rubber pad creating, Warm dealing with, Stretch developing As a top helicopter components manufacturer, Jones Steel Products enjoys to deal with customers in the aerospace, defense, as well as airplane industries.

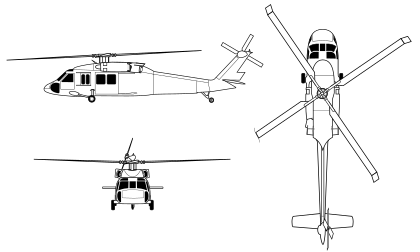

Helicopters are identified as rotary wing airplane, as well as their rotating wing is frequently referred to as the major blades or simply the rotor. Unlike the more typical set wing airplane such as a sport biplane or an airplane, the helicopter is qualified of straight vertical take-off as well as landing; it can likewise float in a set placement.

The autogiro he consequently designed incorporated attributes of both the helicopter and the aircraft, although it resembled the latter more. The autogiro had a rotor that functioned something like a windmill. Once propelled by taxiing cab on the ground, the rotor could produce extra lift; nevertheless, the autogiro was powered primarily by a conventional plane engine.

The Single Strategy To Use For Black Hawk Parts

To steer a helicopter, the pilot has to adjust the pitch of the blades, which can be established three methods. In the collective system, the pitch of all the blades affixed to the blades equals; in the cyclic system, the pitch of each blade is made to rise and fall as the blades rotates, and the click over here 3rd system uses a mix of the very first 2.An associated issue happens because, as the helicopter moves on, the lift beneath the blades that enter the airstream first is high, but that below the blades on the opposite side of the blades is low. The internet impact of these problems is to undercut the helicopter. Usually, the methods of making up for these uncertain variants in lift and drag is to produce adaptable blades attached to the blades by a joint.

Torque, an additional trouble associated with the physics of a rotating wing, triggers the helicopter body (cabin) to revolve in the opposite instructions from the rotor, specifically when the helicopter is moving at reduced speeds or hovering. To offset this response, numerous helicopters use a tail blades, a subjected blade or ducted fan placed on the end of the tail boom normally seen on these craft.

He explored for more than twenty years and finally, in 1939, flew his very first flight in a craft called the VS 300. Tethered to the ground with long ropes, his craft flew no greater than 50 feet off the ground on its very first several flights. Even after that, there were problems: the craft flew up, down, as well as sideways, however not onward.

How Black Hawk Parts can Save You Time, Stress, and Money.

as well as asked to try one of their new major frame office computers. By 1951, Parsons our website was explore having the computer's calculations actually assist the machine tool. His concepts were eventually become the computer-numerical-control (CNC) machine tool market that has reinvented modern-day manufacturing approaches. 1 Each individual tubular part is cut by a tube cutting machine that can be rapidly readied to create various, exact lengths and specified set amounts.For besides minor bends, tubes are full of liquified sodium silicate that sets as well as eliminates kinking by causing television to bend as a solid bar. The so-called water glass is then gotten rid of by putting thebent tube in boiling water, which melts the internal material. Tubing that should be bent to match body contours is fitted over a stretch creating maker, which stretches the steel to an exactly contoured shape.

The last process requires injecting wax or an alloy with a reduced melting point right into a mold or pass away. When the theme has been developed, it is dipped in molten steel as lots of times as required to attain the thickness wanted. When the part has actually dried, it is heated up to ensure that the wax or alloy will melt and also can be put out - black hawk parts.

Report this wiki page